Diamond Blade for Blue Ripper Saw

$151.20

Material:Large Granite Blades Time:24/11/2017

Material Application:Granite

Origin:China

Size:

14"Certifcated:CE / ISO / SGS

Custom Made:YES

Recommendation

Product Description

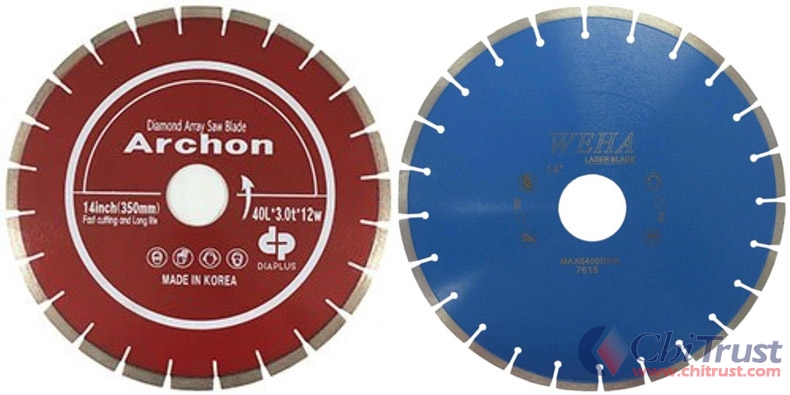

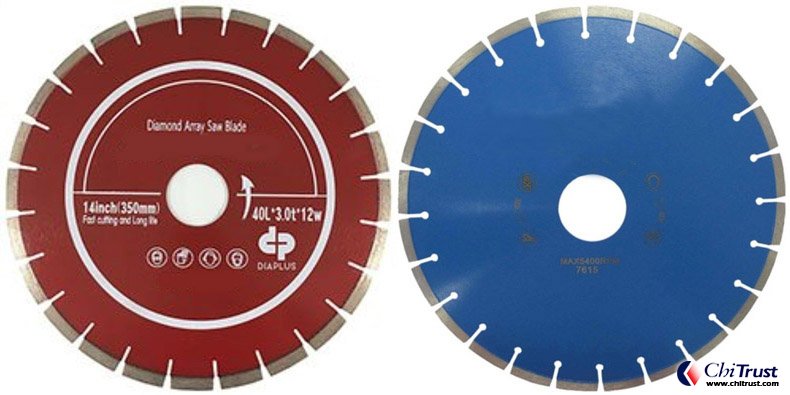

Diamond Blade For The Blue Ripper Rail Saw

Traditionally, fast-cutting diamond blades did not have a long life-span, and long-lasting blades did not cut fast. The granite blade is made to be used with Blue Ripper and other rail saws.

The diamond blade fits on the Blue Ripper Rail Saw perfectly and is made with an array pattern to optimized cutting and performance. The Blue Ripper Blade makes cutting with a rail saw almost as effective as using a bridge saw.

Long life and fast cutting speed were incompatible. Now, both fast cutting speed and long life exist in the same diamond blade - the Arrayed Pattern Diamond Blade.

Features

Diamonds specifically pattern-arrayed in each segment

No more random diamond placement in blade segments

30% longer blade-life than traditional blades

Uniform diamond exposure to the stone surface over entire segment life

No uneven segment deterioration or premature diamond loss

Smoother cut with virtually no chipping

Standard segment height of 10mm

What makes these blades different?

In traditional diamond blades, the diamonds are randomly placed within each segment's bonding agent. As a result, the diamonds are exposed to the stone in an unbalanced, random way. This results in uneven segment deterioration, premature diamond loss, and blades that wear out relatively rapidly.

With the new Arrayed Pattern Diamond Blade, the diamonds are arrayed in a specific pattern in each segment. This groundbreaking technology allows for uniform diamond exposure to the stone surface. The perfectly balanced cutting action provides a fast, smooth cut; and because the patterned diamonds are exposed to the stone at the same consistent rate as all the other diamonds in each segment, the blade life is greatly extended - 30% longer blade-life than traditional blades. There is no uneven segment deterioration or premature diamond loss.

For a long-lasting, smooth, fast-cutting diamond blade the Arrayed Pattern Diamond Blade has no equal!

Specificationsm for the Blue Ripper 14 inch Arrayed Pattern Blade

| Item# | Size | Arbor | Segment Height | Max RPMS |

|---|---|---|---|---|

| ARY1080 | 8" | 7/8" - 5/8" | 10mm | 4300 |

| ARY1014 | 14" | 50/60mm | 10mm | 3450 |

Granite Marble Stone Floor Tile for Flooring and Wall

Color: White, Black, Grey, Coffee, Yellow, Red, etc.

Common size of Granite & Marble tiles:

12" X 12" or 305 X 305mm

16" X 16" or 400 X 400mm

18" X 18" or 457 X 457mm

12" X 24" or 300 X 600mm

24" X 24" or 600 X 600mm

Thickness: 10mm, 12mm, 15mm, 18mm, 20mm, 30mm,etc.

Thickness Toleranc: +/- 1mm,or +/- 2mm,Polished 85 Degree Up.

Usage: Used For Tile, Granite Tile, Flooring Tile, Granite Slab, Marble Slab, Wall Cladding Tile, Momument, Countertop, Kitchentops, Steps, Kerbstone, Paving Stone...etc.

Finish: Polished, Honed, Flamed, Sandblasted, Rough Hammered, Bush Hammered, Mushroom, etc.

Edge Finish: Bevel, Straight, Bull-nose, Round Edge,etc.

Granite is one of the hardest and most durable of all flooring tiles. Granite tile is a perfect choice for hard surface applications where durability and low maintenance is important, such as tiles for kitchen countertops, high traffic floors and tile flooring for commercial applications.

As an elegant & high-end building material,is widely in many housing areas.we invite you to enjoy this visual feast and aunderstand marble interior flooring better.